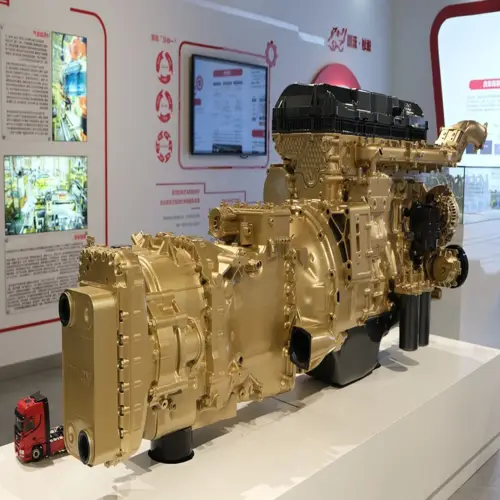

China Transmission Gear Worm Parts Truck Automobile Gearbox with Best Sales

The China Transmission Gear Worm Parts Truck Automobile Gearbox is a highly reliable and convenient transmission system that provides high efficiency. The gearbox assembly uses a fully helical gear and planetary gearbox structure that ensures low noise and a strong load-bearing capacity. The synchronizer friction material’s pressure resistance and overheating resistance are leading domestically, which results in a synchronizer lifespan that matches the gearbox assembly. The DT14 assembly has undergone 2 million kilometers of road validation, and the B10 has a lifespan of 1.6 million kilometers. The gearbox assembly is equipped with hydraulic retarders to ensure driving safety.

Why Choose Our Products

Our products stand out for several reasons:

- Extensive Product Range: We offer various vehicles, including buses, school buses, and special purpose vehicles, to cater to different transportation needs. Our solutions cater to standard public transportation, specialized school buses with enhanced safety features, or even custom-built special purpose vehicles for specific applications.

- Superior Quality and Reliability: Our vehicles meet the highest industry standards, ensuring exceptional quality, reliability, and longevity. We collaborate with reputable manufacturers and conduct rigorous quality control checks to deliver products that exceed customer expectations.

- Cutting-Edge Technology: Our vehicles incorporate advanced technologies and innovations into our vehicles to enhance performance, efficiency, and safety.

- Customization Options: We provide customization options to tailor our vehicles according to specific requirements, including seating capacity, interior configurations, accessibility features, or branding elements.

- Focus on Safety: Safety is our top priority. Our school buses are designed with comprehensive safety features, including reinforced structures, advanced braking systems, and integrated safety technologies. We prioritize passenger and driver safety to provide peace of mind for both educational institutions and parents.

- Exceptional After-Sales Service: We provide reliable after-sales service and support, including spare parts availability, technical assistance, and maintenance guidance. Our dedicated team ensures that our customers receive prompt and efficient service throughout the ownership lifecycle.

FAQ

1. What information do you need to provide a quote?

Please kindly send us the drawing of your product and include:

- Materials

- Surface Finish

- Tolerance

- Quantity

Note that these are essential for our quotation and we cannot provide a specific price without all of them.

2. When can I get the price?

Our professional sales team will respond to your RFQ within 12 hours and provide a quotation within 48 hours if the drawing and specification are all in detail.

3. How can I get a sample to check your quality?

After price confirmation, you can request samples to check our product’s quality. If you need a blank sample to check the manufacturing quality, we will provide a sample after confirming the order.

4. What’s the lead time for Mould and samples?

For normal projects, we can complete the mold and supply the first article sample within 30 to 40 days. For urgent projects, we can deliver the mold and sample in 20 days maximum.

5. What are the payment terms for an order?

For mold/tooling and sample: 50% deposit paid by order, the remaining 50% paid after sample approval. For production orders for new customers, we request a 30% down payment, and the remaining 70% paid by a copy of the original B/L copy. For long-lasting regular customers, we can provide better payment terms, such as 100% pay after delivery or by B/L copy.

All the content of this page is from the Internet and is only intended as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you need to buy original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Worm Gearbox

Worm gearbox offers several performance characteristics that make it an ideal choice for various applications:

- High Efficiency: The worm gearbox provides high efficiency, ensuring maximum power transmission.

- Compact Design: Its compact design allows for easy installation and integration into different systems.

- High Torque: The worm gearbox offers high torque output, making it suitable for heavy-duty applications.

- Smooth Operation: It provides smooth and quiet operation, minimizing noise and vibration.

- Reliable and Durable: Worm gearbox is known for its reliability and durability, ensuring long-lasting performance.

- Self-Locking: The self-locking feature of the worm gearbox prevents it from back-driving, providing enhanced safety and stability.

Types and Characteristics of Worm Gearbox

Worm gearboxes are available in various types, each offering unique characteristics:

- Non-Reversible Worm Gearbox: This type of worm gearbox is designed for one-directional power transmission, suitable for applications where back-driving is not required.

- Reversible Worm Gearbox: Reversible worm gearbox allows for bidirectional power transmission, making it suitable for applications that require back-driving.

- Right-Angle Worm Gearbox: The right-angle worm gearbox is designed to transmit power at a 90-degree angle, allowing for compact and space-saving installations.

Advantages of Worm Gearbox Made of Different Materials

Worm gearboxes can be made of various materials, each offering its own advantages:

- Cast Iron Worm Gearbox: Cast iron worm gearbox provides excellent strength and durability, making it suitable for heavy-duty applications.

- Aluminum Worm Gearbox: Aluminum worm gearbox is lightweight and corrosion-resistant, ideal for applications where weight and environmental factors are a concern.

- Stainless Steel Worm Gearbox: Stainless steel worm gearbox offers superior resistance to corrosion and high temperatures, making it suitable for demanding environments.

Application of Worm Gearbox in Various Fields

Worm gearbox finds its value and importance in various fields, including:

- Material Handling: Worm gearbox is widely used in material handling equipment, providing efficient power transmission for conveyor systems and lifting mechanisms.

- Packaging Machinery: Worm gearbox plays a crucial role in packaging machinery, ensuring precise and reliable movement of packaging components.

- Food Processing: The hygienic design and smooth operation of worm gearbox make it suitable for food processing equipment where cleanliness and efficiency are essential.

- Textile Industry: Worm gearbox is utilized in textile machinery for precise control and synchronized movement of various components.

Future Development Trends and Opportunities of Worm Gearbox Products

The future of worm gearbox products holds several development trends and opportunities:

- Advanced Materials: The use of advanced materials in worm gearbox construction will enhance performance and durability.

- Improved Efficiency: Continuous advancements in gear technology will lead to enhanced efficiency and power transmission capabilities.

- Smart and Connected Gearboxes: Integration of smart and connected technologies will enable remote monitoring and predictive maintenance of worm gearboxes.

- Automation and Industry 4.0: The increasing adoption of automation and Industry 4.0 principles will drive the demand for efficient and reliable worm gearbox solutions.

Choosing a Suitable Worm Gearbox

When selecting a suitable worm gearbox, several aspects should be considered:

- Load Requirements: Determine the torque and power requirements of your application to ensure the selected worm gearbox can handle the load.

- Ratio Selection: Choose the appropriate gear ratio to achieve the desired speed and torque output.

- Type of Gearbox: Consider the specific type of worm gearbox that best suits your application’s needs, such as non-reversible, reversible, or right-angle.

- Environmental Factors: Evaluate the environmental conditions, including temperature, humidity, and the presence of corrosive substances, to select a gearbox with suitable material and protection features.

- Maintenance and Durability: Assess the maintenance requirements and expected lifespan of the worm gearbox to ensure it meets your long-term operational needs.

In conclusion, worm gearbox offers excellent performance characteristics, various types, and advantages based on different materials. Its application in different industries demonstrates its value and importance. The future holds promising trends and opportunities for worm gearbox products, driven by advancements in materials, efficiency, smart technologies, and automation. When choosing a suitable worm gearbox, considering load requirements, ratio selection, gearbox type, environmental factors, maintenance, and durability is crucial for optimal performance.

Author: Dream